New features introduced with the release

X4

Updates:

- November 2020: released the new version X4: download list of new features introduced >

General functions and Supervisor Environment

- New management of the user's manual and online-help in html format that replaces the previous one improving the support on the latest operating systems. The manual can be accessed both from the menu with the command 'Help > Manual > User manual', by pressing the [ F1 ] button and in a contextual way through the dedicated button within the program dialogues.

- Improved language change management, 'Utility > Technical Menu > Change Language': review of the dialog, double click to confirm the selected language and automatic restart of the program at language change.

- Added mouse wheel management in the drw Gdir file opening window 'File > Drawings list'.

- Holding down the [ Ctrl ] key while turning the mouse wheel will perform a VERTICAL PAN of the panel (CAD and CAM environments).

- Holding down the [ Shift ] key while turning the mouse wheel will perform a HORIZONTAL PAN of the panel (CAD and CAM environments).

- Added fine zoom mode: holding down the [ Ctrl ] and [ Shift ] keys while turning the mouse wheel will perform a precision zoom with lower magnification/reduction (CAD and CAM environments).

- Label management: QR-CODE and DATA MATRIX fields introduced.

- With the 'Preferences > General' command you can now set the size of the start/end path symbols displayed during 'Cut and Join' mode in CAD or with 'Display > Routing ends' active.

- Introduced new symbol to indicate CLOSED paths.

- Layer management window ('Layer > Edit'): after deleting a layer the cursor automatically positions itself on the next one after the one deleted, speeding up the elimination of a series of unused layers.

- Improved 'destination folder' selection window. When the dialog opens, the path to the last selected folder will be automatically displayed.

CAD Environment

- Added the print flag display in the layer selection window and improved list navigation via keyboard.

- Added "Mirror in X" and "Mirror in Y" command for tilted machining (3D).

- Enhanced the command 'Path > Routings reduction'.

- Routings global direction:

Replaced the command 'Set > Global direction' with the new command 'Set > Routing direction': you can now distinguish between the direction to be set for open routes (right/left) and the direction for closed routes (clockwise/counter-clockwise).

It is possible also choose which paths to apply this setting to:- all paths in the drawing,

- all paths on the current face,

- all paths on the current layer,

- all paths currently selected (using the apposite button).

CAM Environment and Tooling

- Improoved the tooling dialog.

- Introduced the possibility to move the panel (PAN) by holding down the mouse wheel, in the same way as in the CAD environment.

- Revised appearance and colours of the tool selection list. Increased the dialog height to display multiple tools simultaneously.

- The tool selection list supports scrolling with the mouse wheel and double-click and keyboard for selection;

- Sequence environment: added checkboxes in the machining sequence tree to be used as a reference for moving elements of the sequence.

- Improved manual sequence management `Machining > Manual Sequence > Set':

the sequence modification is not interrupted by clicking on the panel and it is possible to resume the numbering from a specific point by clicking on the entity while holding down the [ Ctrl ] key.

The number of the last clicked entity also takes a different colouring.

- Sequence environment: enhanced sequence recording functionality 'Sequence > Record'. As entities are clicked in sequence to determine their order, they remain in red, making it easier to identify those for which the order has not yet been defined.

- Reviewed view options dialog, 'Options > View'.

- The display dialog of the part-program is resizable and by holding down the [ Ctrl ] key while rotating the mouse wheel, you can enlarge or reduce the font size of the displayed program. In addition, using the dedicated buttons, you can open the folder containing the program or print it.

Finally, to the left of the code, the line numbers are displayed.

NESTING Optional Module

- Improved toolbar management.

- Improved the graphic printing of nesting layouts: added the management of rectangular pieces rotated by any angle, polygonal pieces (i.e. whose cutting path is made up of straight lines) and circular-shaped pieces.

- Creation of additional layouts for entities on the lower face of the panel:

it is now possible to add drawings containing machining on the lower face of the panel to the NESTING list. In this case the Nesting Module will automatically generate 2 layouts: the first containing only the machining of the lower face and a second layout for the machining on the upper face. The machine operator will first process the layout with the lower face machining, then complete the layout by tilting the panel and machining the upper face.

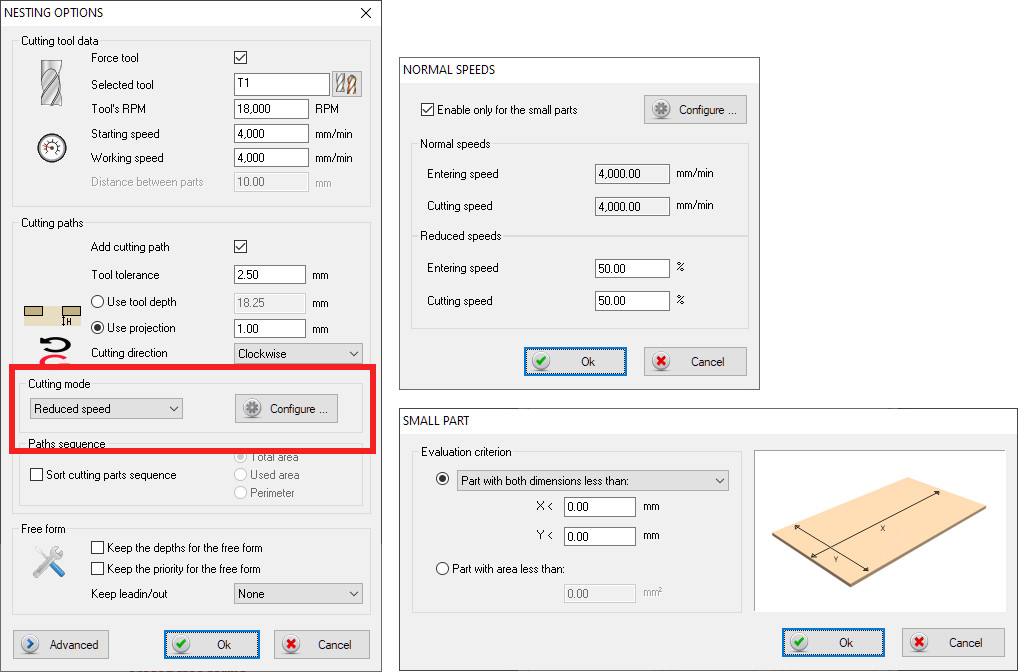

- Introduced new low speed machining strategy for 'small' parts. This mode is now available among the [ Cutting Modes ] options accessible via the command 'Process > Processing Options' as an alternative to onion-skin and tabs.

- File creation for automatic label printers (for supported configurations). The generation of all the files required by the automatic label printers (labels, lists, previews) takes place automatically during the generation of the machine program of the nesting scheme.

Macro

- New macro command ~GetToolId

~GetToolId(TypeLav, IdxLav) function can now be called from macro/processor to obtain the ToolNumber (or ToolCode) of the tool assigned (also automatically) to the machining specified by the parameters provided.

Note: The existing ~GetTool command only returns this information if the machining has been manually assigned. - New macro command ~FolderSelect

displays folder selection dialogs in the style of Win7/8/10.

~LET [ret] = ~FolderSelect(, "folder_name")

Unlike the ~FolderSel function which always shows the complete folder tree, ~FolderSelect opens the dialog at the location specified in "folder_name". - New macro command ~SplitWideArc

Breaks the provided arc into 2 (or 3) equal parts if the angle it underlies is greater than 180° (or=360°)

~LET [ret] = ~SplitWideArc(<idx>) - Revised Macro manual 'APL Language Ref', which can be found in the program installation folder inside the 'PDF' folder.

Other improvements

- Strategy Layer Import: it is now possible to define among the processor parameters, within the import profile, a series of layers to exclude from the import. All entities belonging to these layers will not be imported.

- Management of CUTTER tools;

- PGMX format support for SCM machines with TWIN HEAD machine management.

- New distribution format: the program is now distributed not only as a digital download or CD-ROM, but also on a USB stick with new packaging and documentation.

- Vacuum cups environment: it is now possible to activate the 'transparent' mode of the panel in order to visualize the machinings present on the lateral and lower faces.

In addition to the usual visual positioning using the mouse, the possibility of manually specifying the height of the vacuum cups through a dedicated window has been added.