New features introduced with release

X6

Updates:

- November 2022: released the new release X6: download list of new features introduced >

General functions and Supervisor Environment

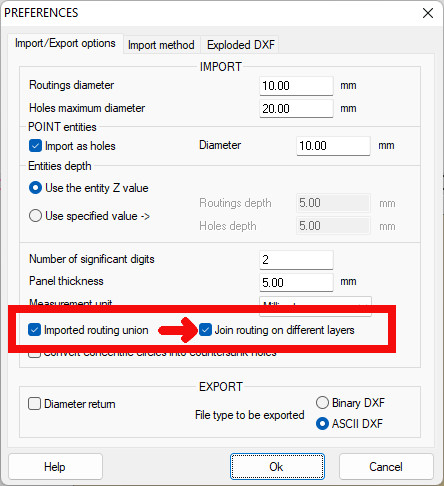

- "Import / Export > Preferences":

added new option "Join routings on different layers". If the option is enabled during DXF import it allows joinining in a path for adjacent routings that belong to different layers.

CAD Environment

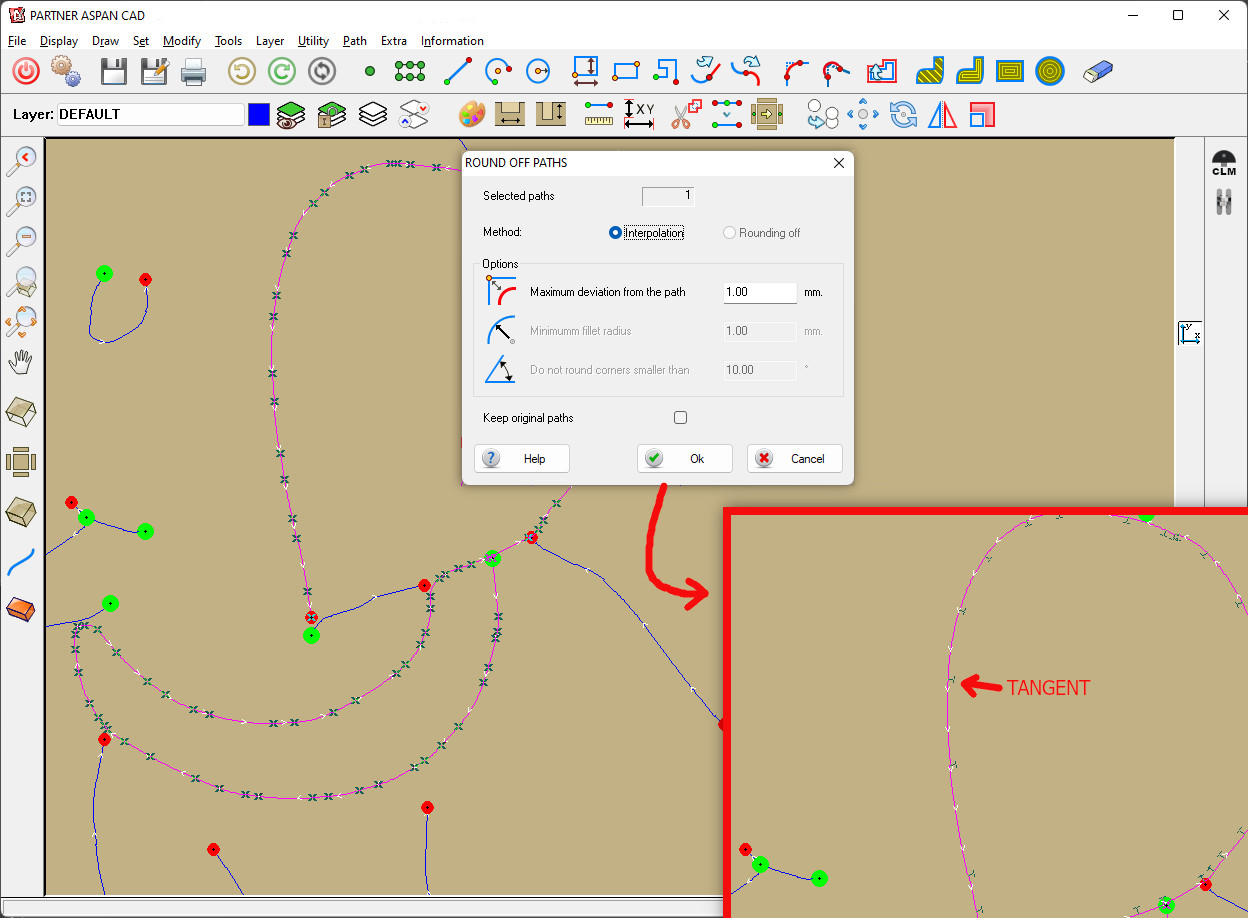

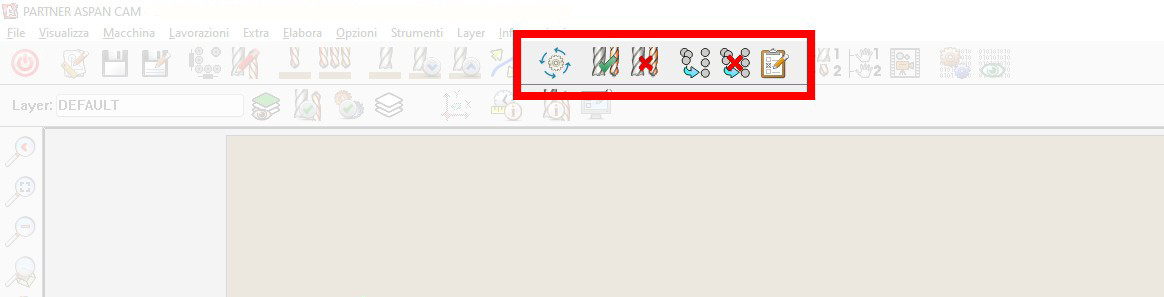

- New command "Path > Sand":

given a path composed of several segments, the "sand" command allows the profile to be smoothed while maintaining the tangency between the segments that make it up.

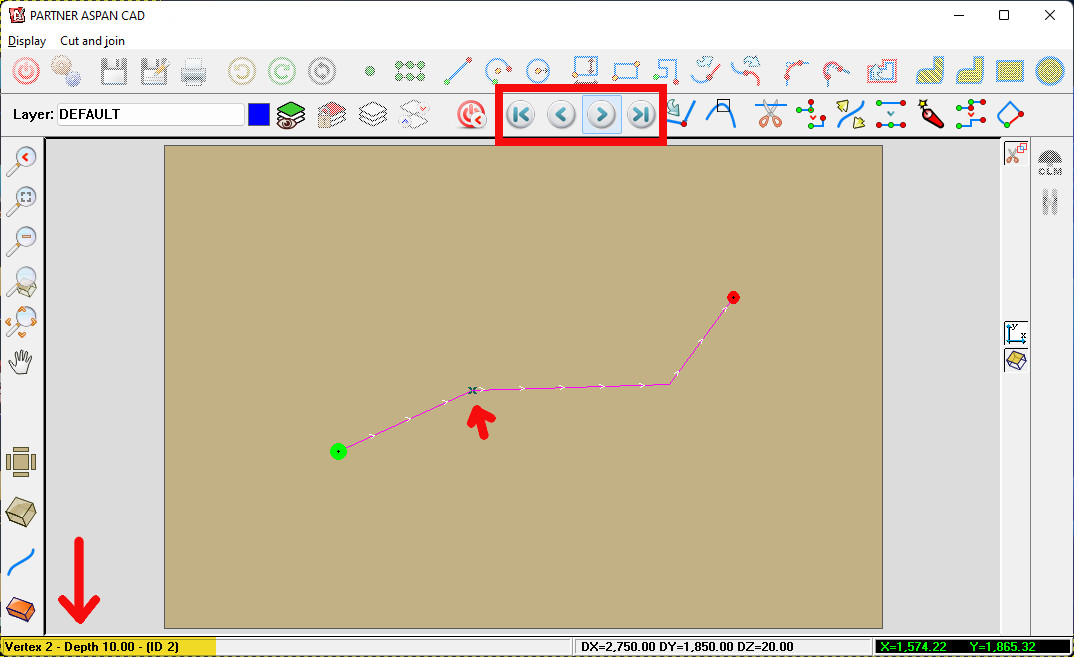

- "Path > Cut and join":

by scrolling through the vertices of a path, in the status bar at the bottom left of the program window, the index of the selected vertex, the depth and the ID of the current section are displayed.

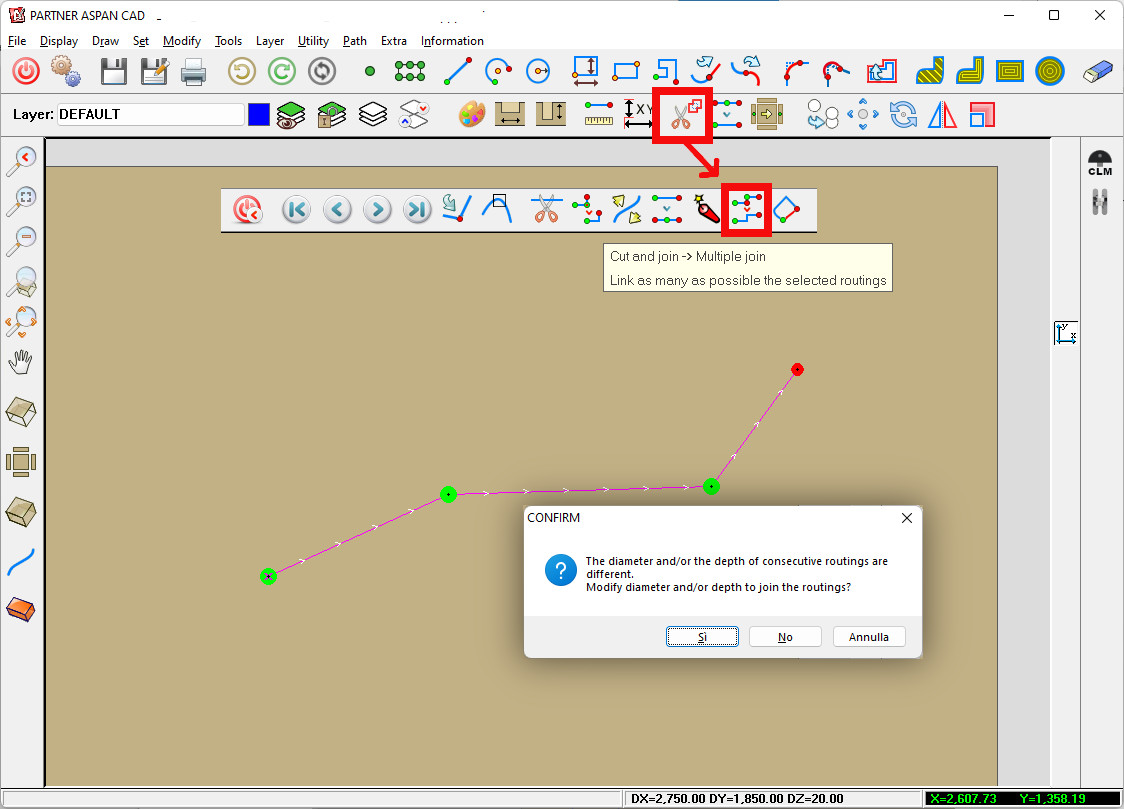

- "Path > Cut and Join > Multiple Join":

when joining several segments to form a single routing path, the command checks that all entities have congruent characteristics and therefore have the same diameter and equal depth at the joining points.

If one of these requirements is not met, similarly to the "Auto Join", command, a message warns the user and proposes to automatically correct the parameters of the lines before the merge operation.

- "Path > Cut and Join > Multiple Join":

optimised the lines merge functionality especially with regard to the calculation of machining direction and depth management.

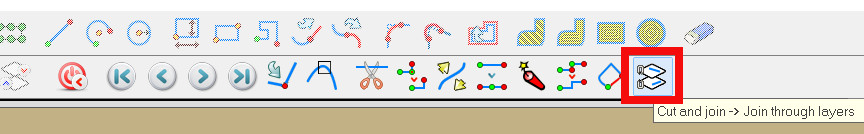

- "Path > Cut and Join > Multiple Join":

the new flag "Join through layers", when active, allows adjacent routings to be joined even if they are on different layers.

Disabled: (default) lines belonging to different layers cannot be joined.

Disabled: (default) lines belonging to different layers cannot be joined. Enabled: multiple join also merges lines that belong to different layers.

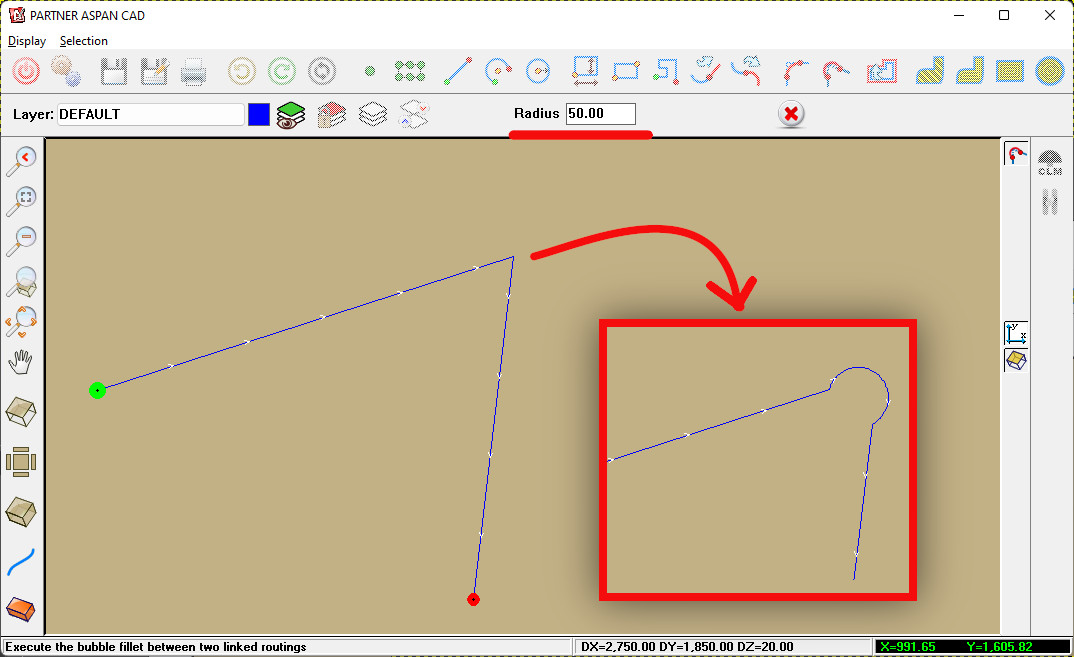

Enabled: multiple join also merges lines that belong to different layers. - New command "Tools > Bubble fillet":

creates a bubble connection between two adjacent entities.

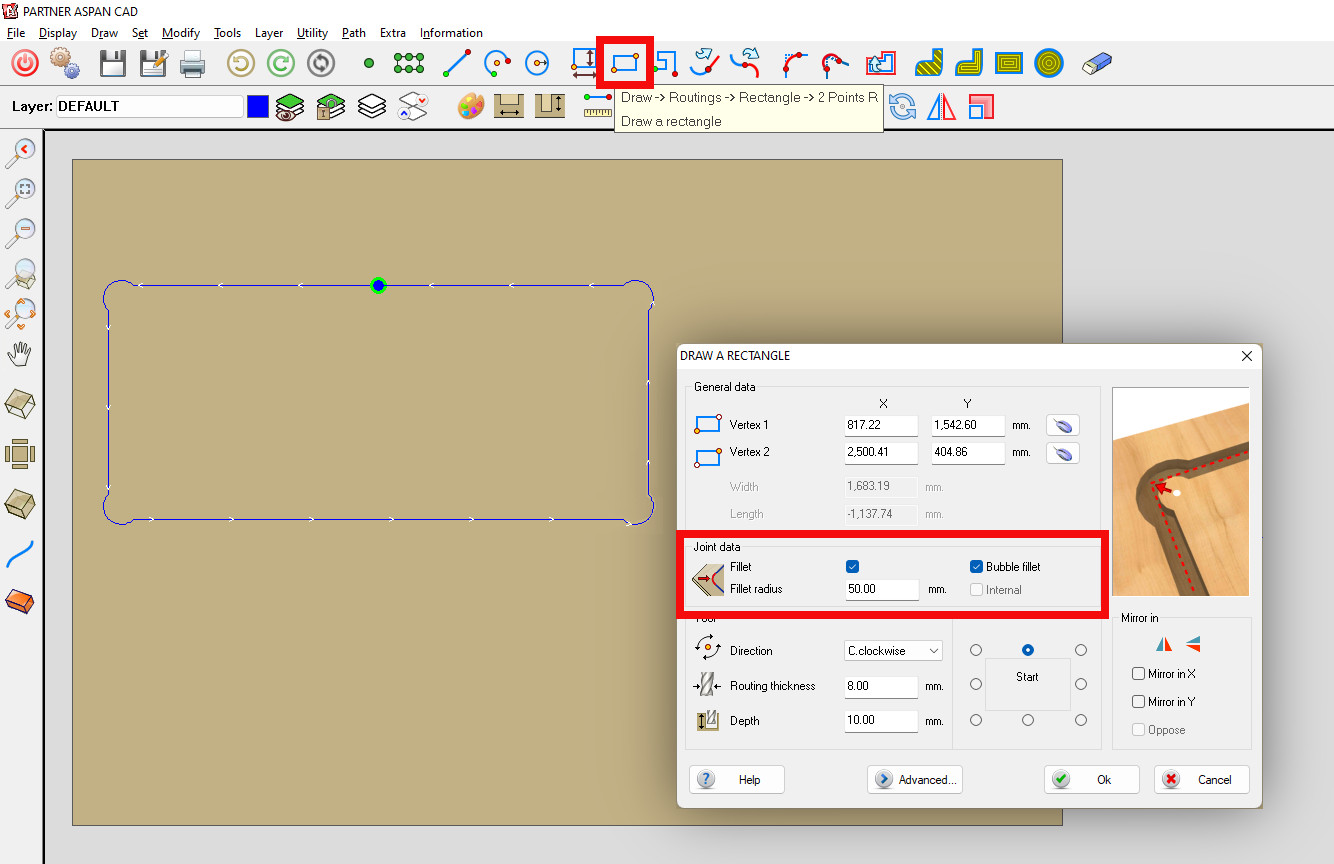

- "Draw > Routings > Rectangle":

the rectangle creation dialog box now allows the automatic creation of bubble fillet on the corners of the rectangle created.

- "Modify > Entity":

created new quick access for the modify entity command, which can now be executed by pressing the key [ N ].

CAM Environment and Tooling

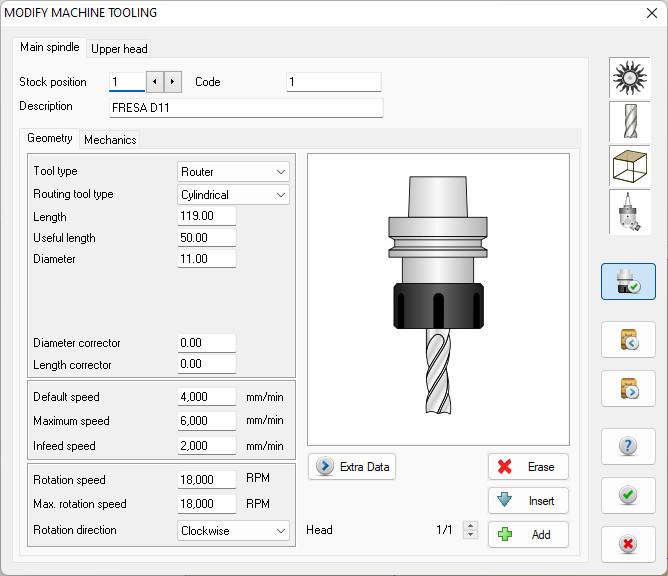

- "Machine > Machine Tooling > Edit":

improvements to the tool data dialog.

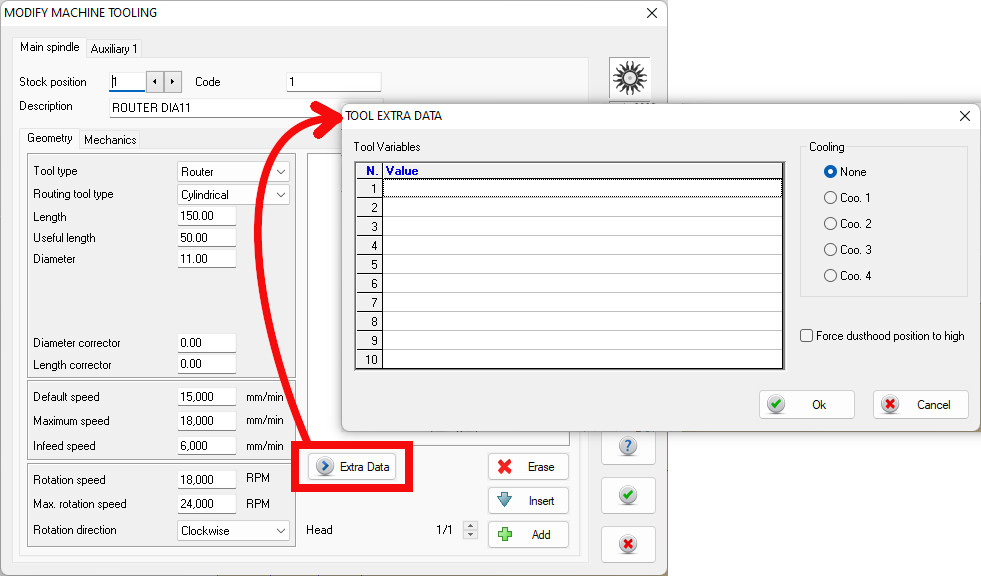

- "Machine > Machine Tooling > Edit":

new section for tool "Additional Data".

For each tool, it is possible to specify Additional Data that can be used by enabled processors to perform particular functions. It is also possible to specify coolant/lubrication options and force the dust hood in high position when that particular tool is used.

For each tool, it is possible to specify Additional Data that can be used by enabled processors to perform particular functions. It is also possible to specify coolant/lubrication options and force the dust hood in high position when that particular tool is used.

Note: These features are only available for enabled processors.

Please contact Atool Software for verification.

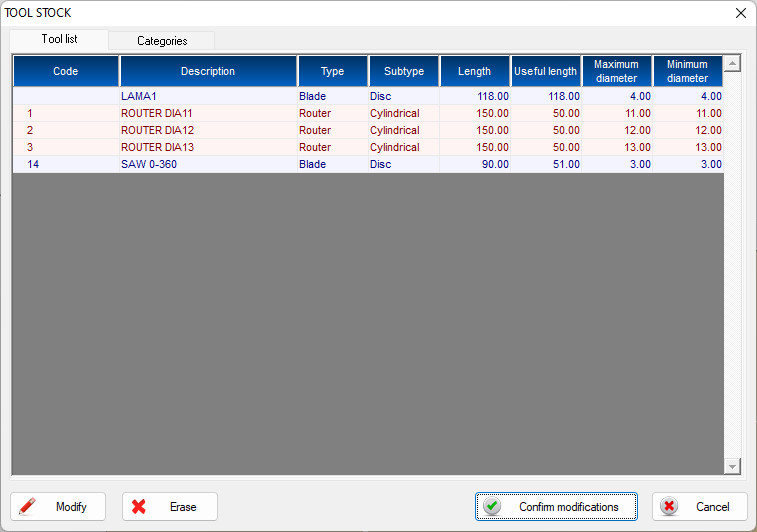

- "Machine > Machine Tooling > Stock":

improved stock management window and added [ Delete ] button to quickly remove unnecessary tools from the stock.

- "Machine > Machine Tooling > Stock":

tools saved in the stock now also retain the mechanics data and additional data introduced with this version.

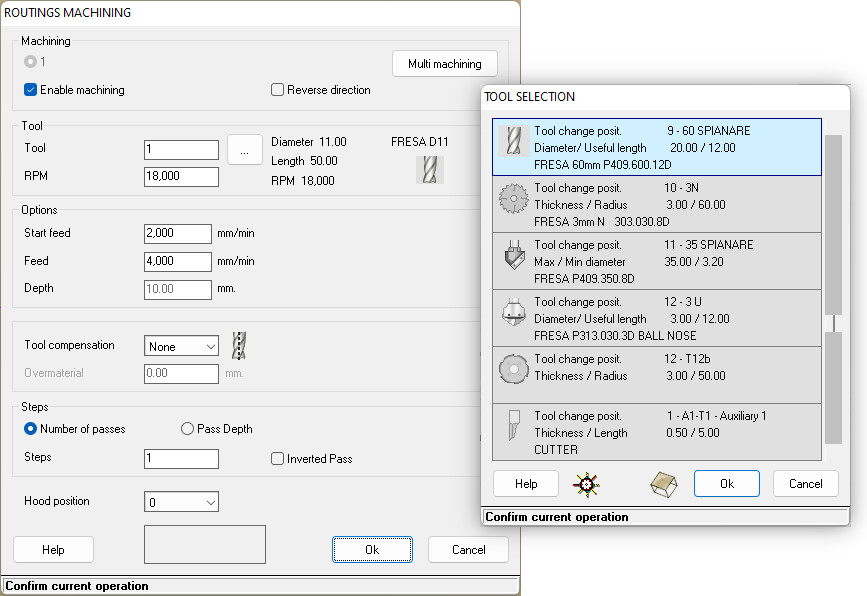

- New Tool Assignment and Optimization managemet:

the new tool assignment and optimisation management makes it easy to decide when and how the program should perform automatic tool assignment and sequence optimisation operations.

This working mode integrates and complements the pre-existing ones.

More information about this new functionality can be found in the following document:

ats_x6_new_tool_assignment_and_sequence_management.pdf >>

- Improved machining property and tool selection dialogues.

NESTING Optional Module

- Improvements to "Onion Skin" management and start point calculation.

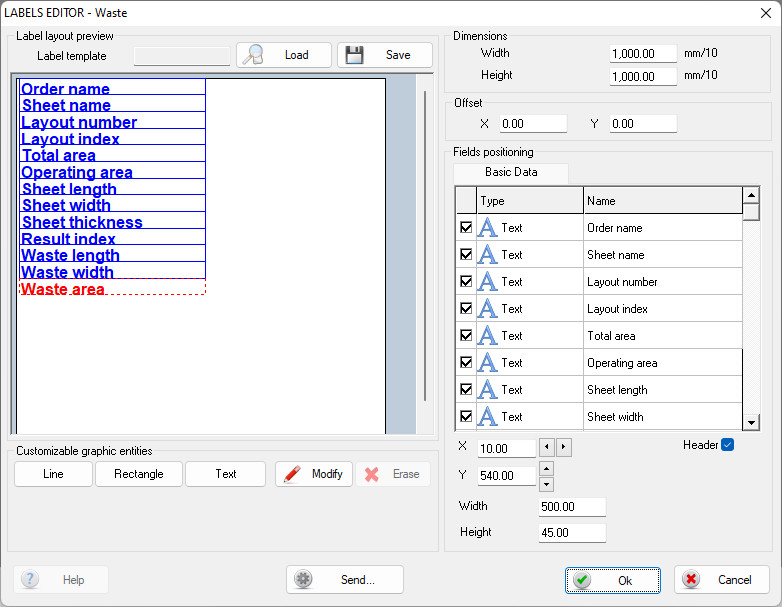

- (automatic labeller) Labels > Configure for waste sheets": waste sheet label management. It is possible to create a customised label to be applied to the waste sheet to be re-stocked.

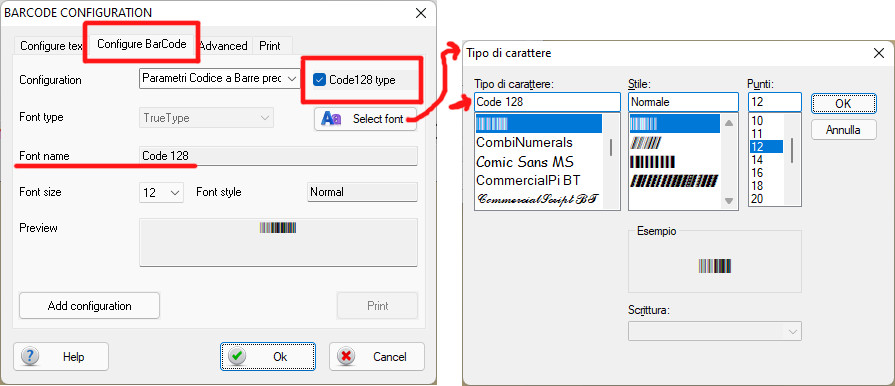

- Code-128B barcode support:

* 'Code 128' font is not included with the program but is easily retrievable online.

Macro

- Optimisations to hardware macros;

- Post-Processor developers can now use tool variables to manage special characteristics, special machining operations, and to uniquely identify a particular type of tool. Data written in "tool variables" are passed to the processor using the variables TOOL_VARIABLE_N, where N is a number from 0 to 9.

- Added post-processor variable [COOLING] that returns a value between 0 and 4 depending on the option selected for lubrication of the current machining. (INIT_SHAPE)

- Added post-processor variable [DUSTHOOD_FORCED_UP] with values 0 and 1 indicating whether the flag "Dust Hood force position high" has been activated. (INIT_SHAPE)

Other improvements

- Added support for new CNC machines.